Rad Lab

Rad Lab

In the heart of Seattle, there's a nondescript warehouse nestled in an old industrial neighborhood.

Years ago, it was used to manufacture maritime equipment. These days, it's the secret headquarters of the Rad Lab, the braintrust for Rad Power Bikes.

Sure, it may not have a glass-enclosed ceiling or a view of the Space Needle like this, but what goes on inside is just as awe-inspiring. Behind these doors, Rad's top minds work tirelessly to craft the world's best electric bikes.

They're the creators of innovative rides, like the RadRover electric fat bike, the RadWagon electric cargo bike, the RadMission electric metro bike, and the upcoming ████████, a new ████████ that some predict will change the ebike game forever.

How does this team of expert ebike enthusiasts do it? We're glad you asked. For the first time, we're giving you a peek inside the Rad Lab.

Engineers

There are three Rad Scientists who make every new creation possible: the Product Manager, the Industrial Designer, and the Engineer.

Once the crew has been assembled, then comes the hard part.

“As one of the earliest innovators in the ebike world, we only take on a project if we are 100 percent sure we can do it better than anybody else,” says Founder and CEO, Mike Radenbaugh.

Great things come from big ideas. Whenever our team realizes there’s something out there that’s never been done before, the Rad Lab steps in to meet that challenge.

This process is led by an internal champion, a stalwart defender of all things Rad: the Product Manager.

As the team’s go-to idea generator, they keep their eye on the big picture, seizing new opportunities and identifying the types of riders a new model could be a game-changer for.

After collecting the team, they draft up the secret plans and lead the way.

Engineers

We are a mobility company and are always looking for the most energy-efficient, enjoyable, and accessible way to get from point A to point B.

The Designer starts by taking a deep look at the wide world of bikes and other modes of transportation to figure out what is and isn’t working for the average cyclist. Are people looking for a different ride feel? Is there something they just can’t do without?

Getting to the bottom of questions like these requires a lot of research.

When our designers discovered that riders were hungry for a low-cost, high-value cargo bike, they blazed new ground with the RadWagon electric cargo bike. When they learned that city-dwellers were often torn between a moped-style ride and a traditional, acoustic bike, they laid the groundwork for the RadRunner, the first single-speed electric utility bike to offer riders the best of both worlds at an affordable price.

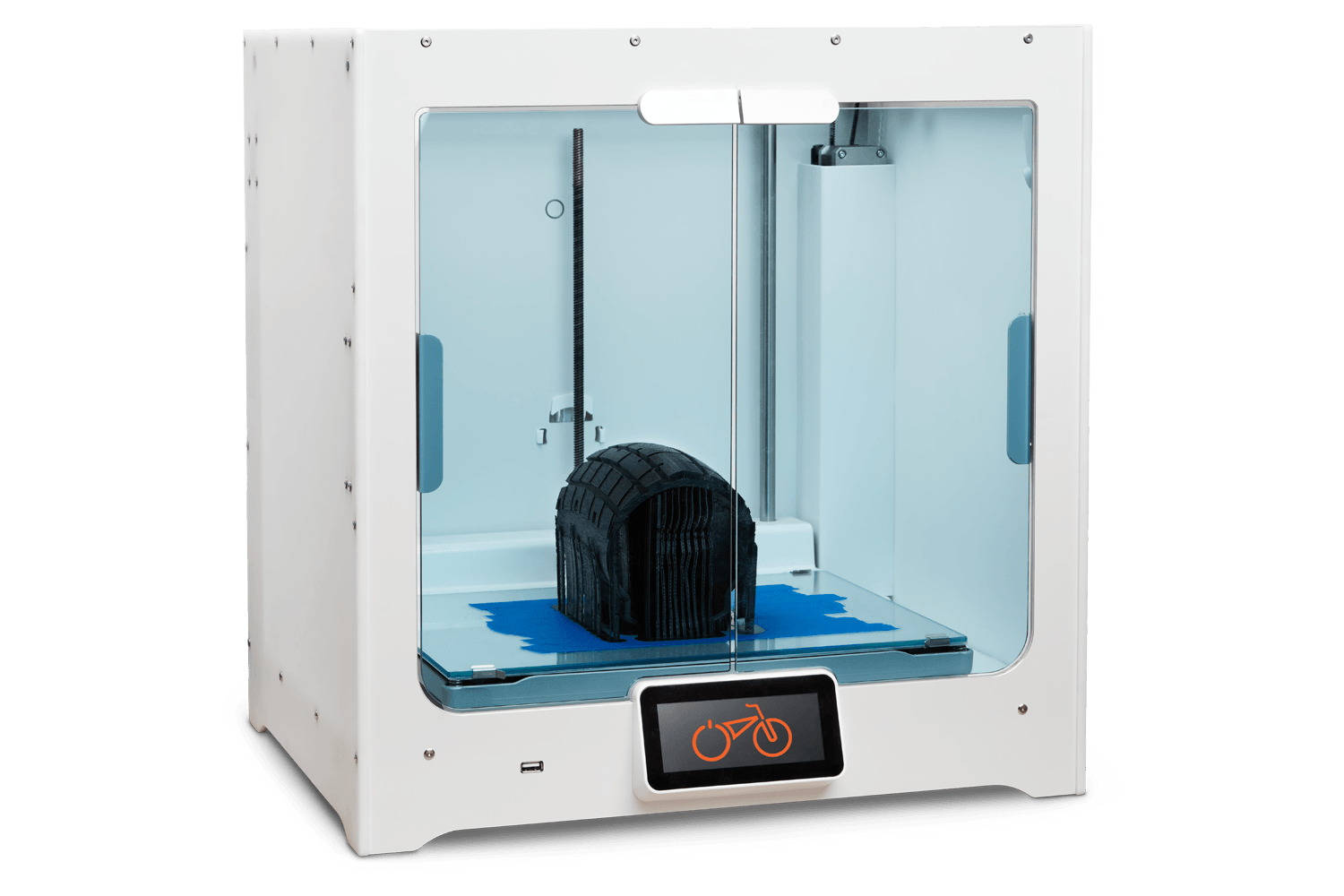

Once they compile a detailed list of must-haves, the Designer hunkers down and gets to work on next steps. This means filling up notebook after notebook with sketches, making advanced computer-rendered models, and printing 3D prototypes.

The Industrial Designer takes the initial rough sketches and renders them through advanced digital modeling.

With a 3D printer, the Rad Lab can iterate in days what would take months to do through a factory sample process.

It takes the Industrial Designer’s computer renderings and turns them into a tangible object that the team can hold in their hands. It’s an important tool for testing the fit, size, and ergonomics of our components before they’re manufactured with the official production materials.

The engineer will take what the industrial designer has envisioned and bring it from notebook to real world.

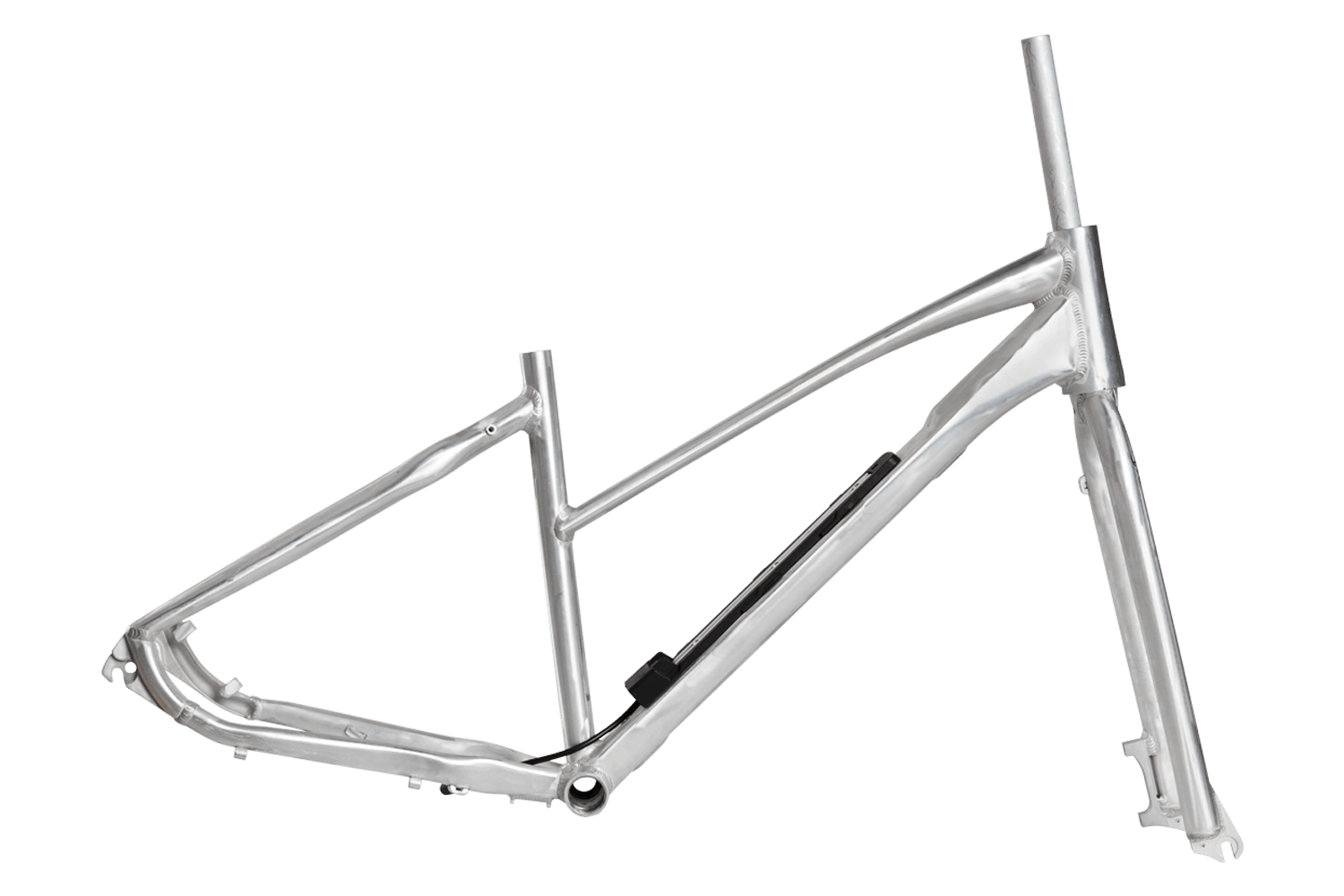

Our frames are engineered to meet U.S. Consumer Product Safety Commission guidelines, and while that may be enough for some bike companies, our engineers go above and beyond to meet the stricter criteria laid out by the European Committee for Standardization.

This process requires putting our frames through multiple rounds of fatigue, durability, and impact tests, including dropping the frame and mechanically simulating an extreme ride. If any visible cracks or fractures appear, the engineering team goes back to the drawing board.

The Rad Lab’s personal standards are even higher, though, and the entire engineering process is a journey of continuous improvement in pursuit of the perfect ride.

For every ebike designed, we go through a series of functional prototypes. We start with a bare bones, unpainted sample to test the geometry of the frame, see how the components complement each other, and test comfort and fit for riders big and small.

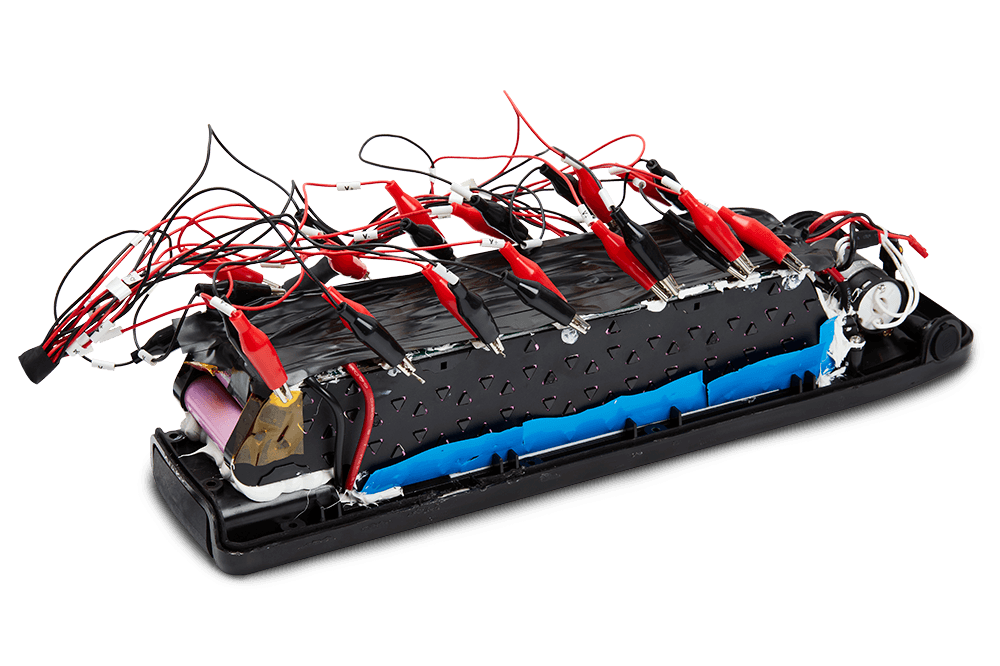

While the Designer and Engineer work closely to test different combinations of components, our electrical engineering team focuses on the battery, motor, and all of the ebike’s tech. They zero in on what each model needs to help riders conquer hills or ride farther with each full charge.

Because without electricity, an ebike is … just a bike.

Before proceeding with a new part, the Rad Lab receives raw, unpainted samples from our factories to ensure that they will be manufactured to the Lab’s exact specifications.

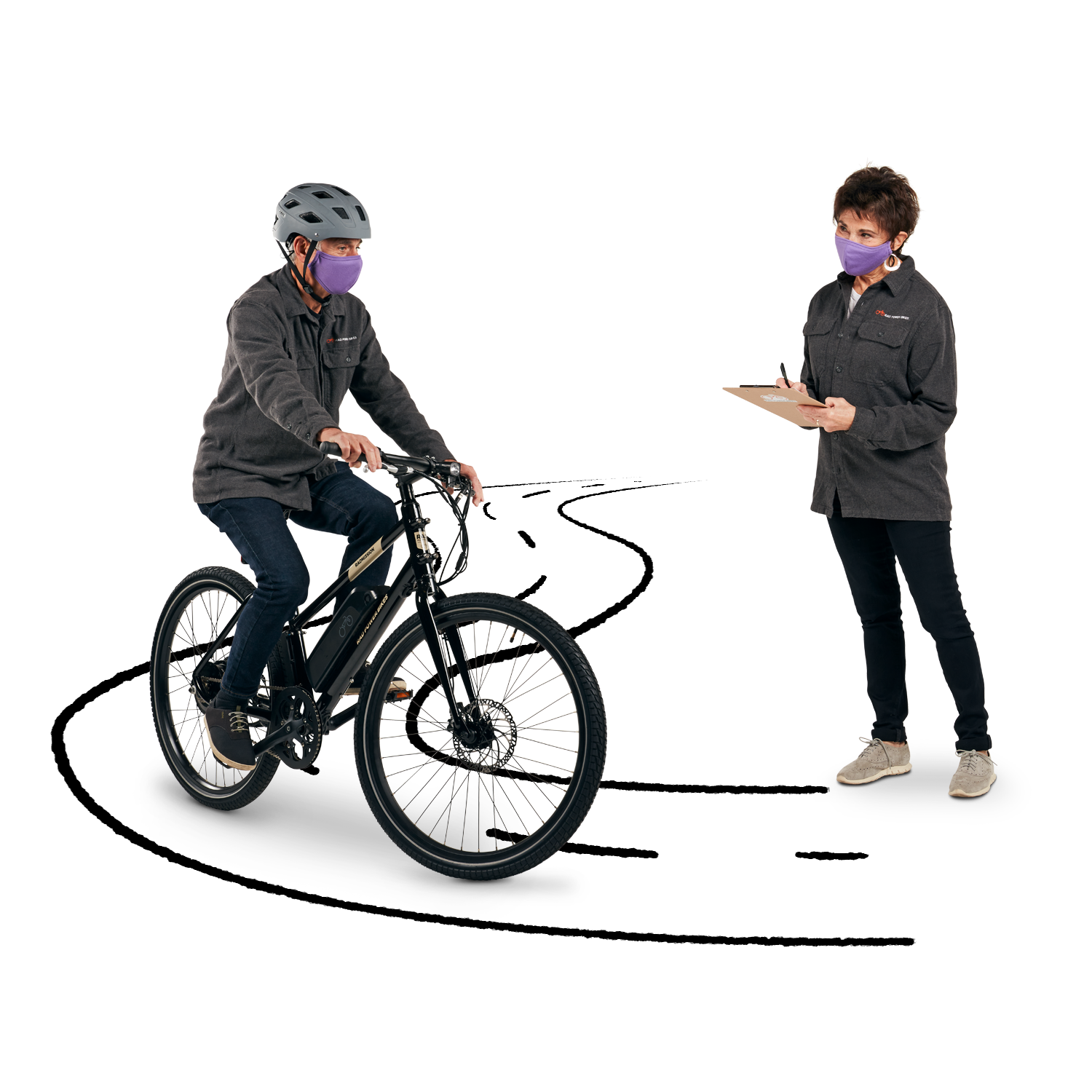

To test ride a new bike in real-world situations without tipping off the riding public to new designs, the Rad Lab creates a camouflaged test ride “mule” -- a bare-bones version of the latest model, usually covered in tape so we can hide our logo from prying eyes.

Since motors, speed controllers, and batteries all have dynamic tension with one another, achieving a smooth, reliable ride can be a bit of a balancing act. Our electrical engineers test each component to ensure they will work in perfect concert with the entire system.

After the team’s worked out the nuts and bolts, we bring on the next round of prototypes.

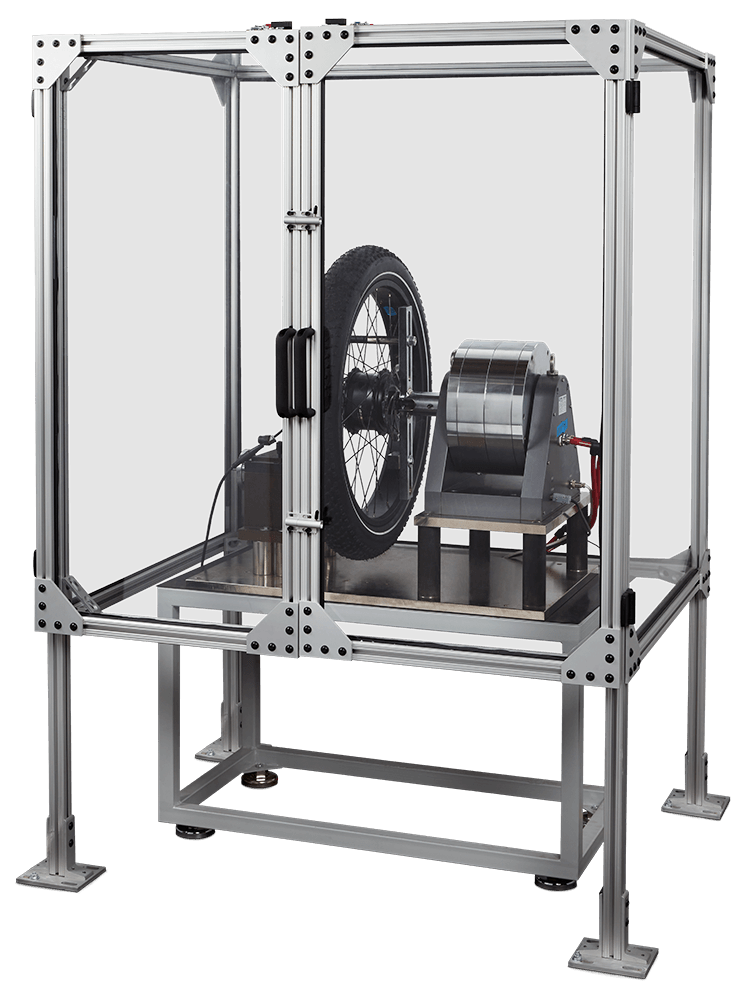

These prototypes are put through rigorous testing. Some of it’s high-tech, like the motor testing dynamometer pictured below, which we use to verify that our bikes are built for the long haul.

Other steps are more hands-on, like giving everyone on the Research and Development team and other departments a chance to test out the new bike on their own.

We’ll even try to actively demolish the bikes to ensure they’re built to withstand the roughest riders and terrains.

(As you can probably imagine, this part’s pretty popular.)

To ensure the best possible performance from our motors, the Rad Lab turns to the dynamometer -- AKA “the Dyno.” This machine lets the team test direct drive and geared hub motors for torque, speed, and responsiveness, which in turn helps them fine-tune your overall pedal-assist experience.

After we’ve worked out all the kinks, we receive the “Golden Sample,” a 100 percent complete bike that is exactly what our customers can expect once the new model goes into production.

If this passes the final barrage of tests, including real-world biking experiences, it’s time to start manufacturing.

But our commitment to quality doesn’t end there. We have full-time quality control teams on the ground at every factory, in every country to make sure each batch is fully inspected before it reaches our riders’ doorsteps.

The Quality Control team at our manufacturing facilities performs a 50-point inspection on the bike after it gets off the assembly line. It’s so in-depth, they’ll even examine the torque on the screws to make sure everything’s just right.

After that, they’ll take it on one last test ride through a 100-meter loop that includes flat stretches, inclines, and an indoor re-creation of the bumpy terrain you may encounter in the wild.

Then we package it all up and send it your way.

When the bike arrives at our rider's doorstep, they're probably too excited to spend much time thinking about the box.

Nevertheless, like everything else that comes out of the Rad Lab, this is an area where we’re constantly making advancements.

As an example, our latest model, the RadMission, comes in our most environmentally-friendly packaging to date. To account for a 52 percent decrease in plastic, we replaced foam with corrugated cardboard, used paperboard handles instead of plastic, and even reduced the number of zip ties included.

Some of our riders in select regions pick up their electric bikes from our showrooms or have them built and delivered by our Mobile Service team.

Others enjoy putting their new ride together themselves. Since we design our bikes to be easily assembled -- and include a wealth of physical and digital tools to help along the way -- it’s a quick, hands-on experience that gives them a chance to learn more about their model.

Either way, once Rad Riders get a chance to hop on their new bikes, they can feel confident that they’re riding a piece of machinery that’s been crafted from the ground up with skill and care.

But that doesn’t mean we’re ready to rest on our laurels. Our hundreds of customer support representatives are constantly listening to the voices of our riders and helping convey feedback across the entire company. We’re always eager to hear from our riders. They’re our Rad family.